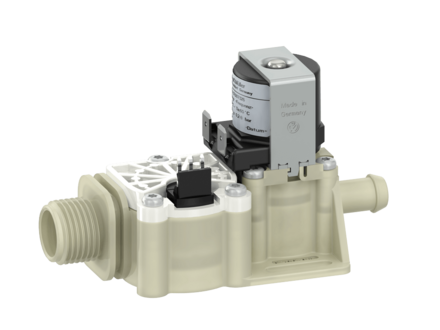

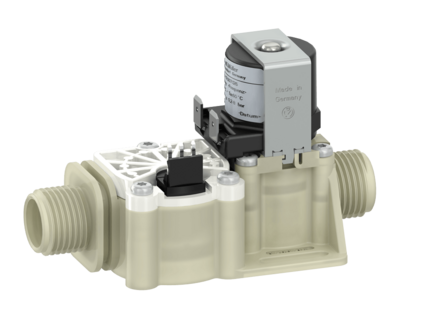

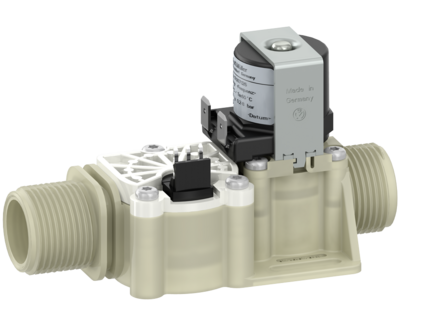

Flow meter turbine, with shut-off device

The combination of a flow meter and a solenoid valve in one compact unit enables, with suitable electronics, the accurate metering of a liquid together with the ability to interrupt the flow.

A servo controlled valve avoids water hammer when connected to the mains supply.

This unit can be used for measuring, feedback control or dosing as it ensures accurate measurement of liquid volumes. The simple internal pulse transmitter offers a long life time without risk of failure.

To avoid air entry causing inaccurate measurements, the flow meter is sited upstream from the solenoid valve.

The flow meter's output are pulses, where the frequency or the number of pulses are equivalent to flow rate or volume.

Depending of the orifice used different measuring ranges can be achieved.