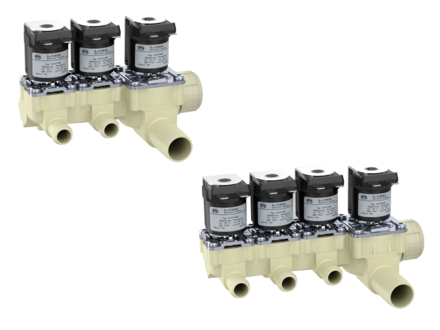

Servo-controlled solenoid valve NC, three- / fourfold, DN 10, DN 17

2/2-way solenoid valve combination of nominal diameters DN 17 and DN 10 for use with cold and heated potable water and physically and chemically similar media. The valve is servo-controlled and normally closed (NC).

Valves of this design are three- or fourfold valves with one common inlet. Each outlet can individually or in any combination be operated.

Coil systems for common voltage and frequency ranges are available.

Electrical operating safety is achieved by insulation class F and can be supported by an integrated protective circuit.

By using high quality insulation materials, continuous duty (100 % ED) at higher medium temperatures is possible. The PA 6/6 valve body persists hot water. Protection against corrosion of inner parts exposed to the medium is achieved by using stainless steel.