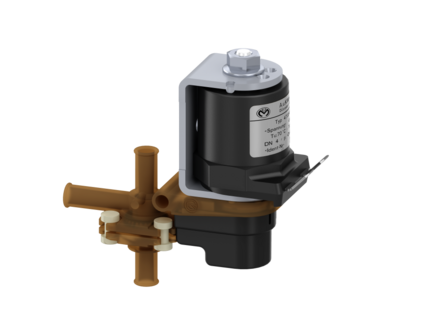

3/2-way lever valve, DN 4

Direct acting 3/2 way solenoid change over valve with different orifice sizes for control of neutral gases and liquids. The plunger of the magnetic system is protected by spatial separation from the medium .

Valves of this design are single chamber valves with nozzles connections. The coil system can be customised for common voltage and frequency ranges on request.

Electrical operating safety is achieved by insulation class F and can be supported by an integrated protective circuit.

Due to the use of high quality materials, the valve is applicable for high ambient and medium temperatures.

Highly suitable for using in laboratory and analysis equipment.