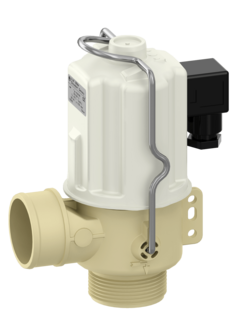

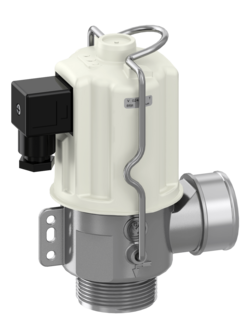

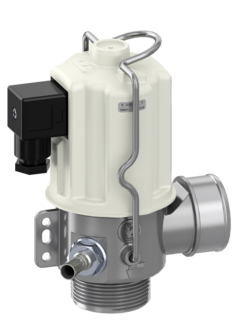

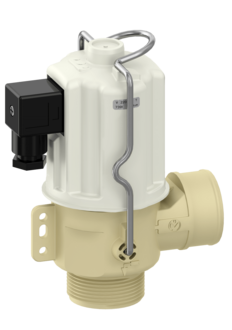

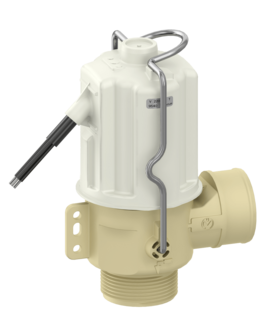

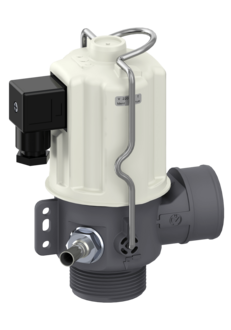

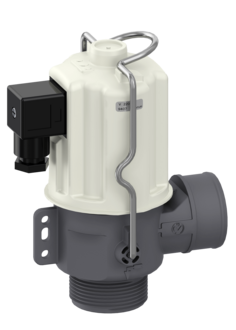

2/2-way drain valve NO, DN 40 IP 65, IP 68

2/2-way direct acting dump valve of nominal diameter DN 40 for controlling low aggressive liquid media, such as cleaning or disinfection agents, direct acting with normally open operation mode NO (normally open).

Valves of this type are medium separated having a single chamber valve body with the inlet at ninety degrees to the outlet. They can be manufactured in various materials and equipped with threaded or hose connections.

The electrical operational safety is guaranteed by the electrical insulation coordination, which corresponds to the VDE 110 regulations. The manufacturing process includes a 100% electrical safety test in accordance with the VDE 0631 Part 1000 regulations.

Protection type IP 68 is achieved in conjunction with cable connection, IP 65 by using a mounted connector.

Valve housing made of PPE or stainless steel are suitable for hot water. Valve housing made of PVDF have a higher resistance to chemicals where stainless steel has both features.

The smooth internal shape improves liquid flow and avoids dirt traps. The valve bodies can be equipped with an additional flush spout.