Float Valve, DN 10, Straight Valve

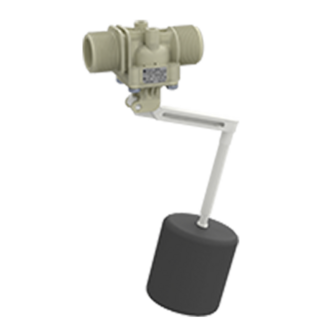

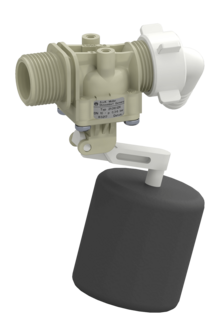

The DN 10 float valve in the straight-through version is a servo-controlled diaphragm valve that closes by the buoyancy of the float to regulate the level in containers.

The float valve automatically replenishes the water when it is removed from the tank, thus keeping the level constant.

If the water level rises and lifts the float in the container, the inflow is reduced in proportion to the position of the float lever. Overflowing of the tank as a result of too much inflow into the tank is thus effectively counteracted.

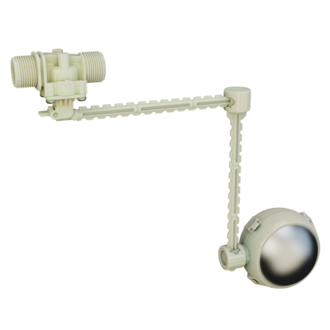

The float valve is a 1-chamber globe valve made of glass-fibre reinforced polyamide. It can be manufactured with different housing connections.

The PE float is suitable for heated water up to 60 °C.

The float valve can be equipped with a multi-position lever. The universal lever can be adapted to a wide variety of tank geometries without tools. In addition, the lever can be shortened for use in smaller tanks. With the optional stainless steel float ball for the multi-position lever, the valve is suitable for heated water up to max. 90 °C.