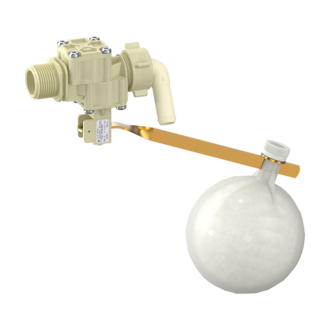

Back-suction Safe Float Valve, NC, DN10, Two Chambers in a Row

In industrial applications, containers are usually kept at a constant filling level by using float valves.

Valves of this design are 2-chamber globe valves and have an additional back flow preventer to provide additional protection against backsiphonage of service water into the drinking water network in accordance with DIN 1717. In addition to the extra safety, this also enables KIWA-compliant use. The valves can be manufactured with different housing connections.

The valve in the chamber on the outlet side regulates the inflow via the float lever. A sealing element in the chamber on the inlet side prevents back-suction from the tank into the inlet pipe.

If the liquid level in the tank drops, the float valve automatically replenishes and thus keeps the level constant.

If the water level rises and lifts the float in the tank, the inflow will get reduced in proportion to the position of the float lever. Overflowing of the tank as a result of excessive inflow during initial filling of the tank is effectively prevented.