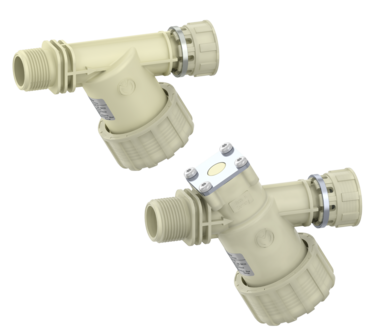

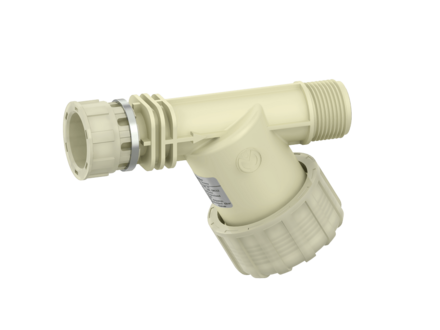

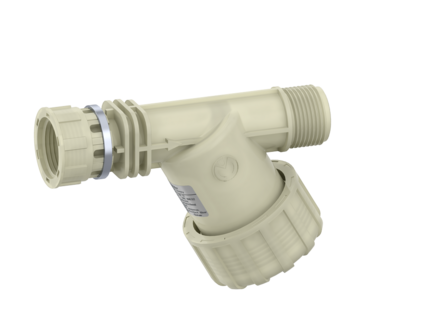

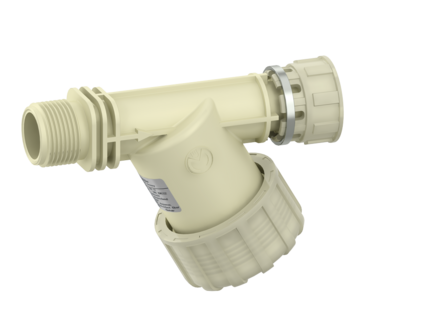

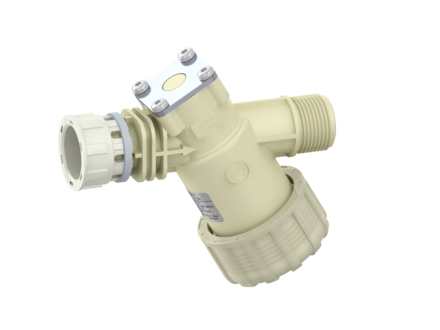

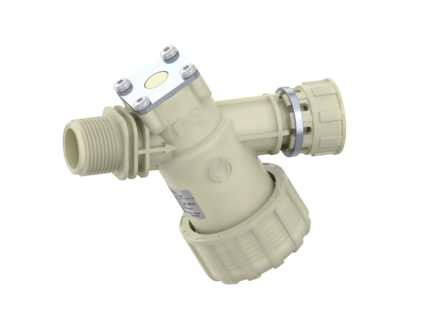

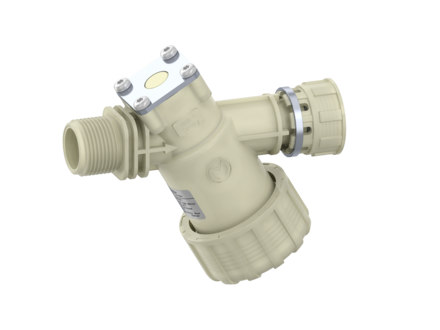

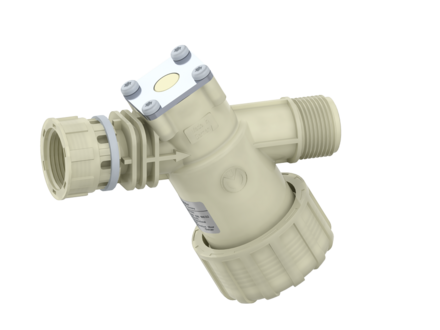

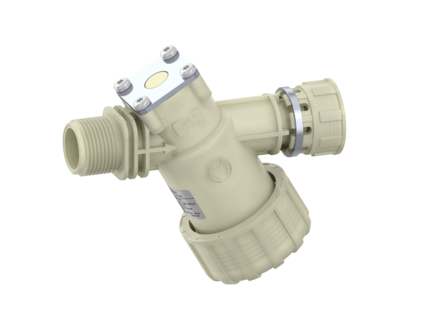

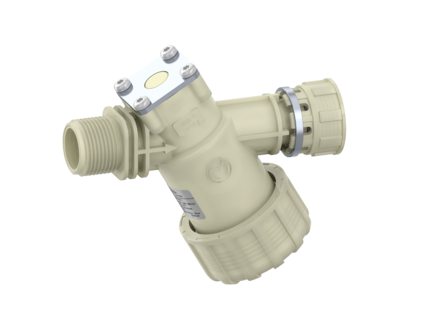

Dirt Strainer, DN 17

The treatment of drinking water by the use of mechanical acting filters and their design is regulated in DIN EN 13443.

The upstream mounted strainer will protect taps and other equipment against damages or malfunctions caused by suspended particles.

There is no need to disassemble the strainer nor tool to replace the filter insert. It is recommended to mount the strainer with the filter insert preferably downwards, to avoid that collected dirt remains in the housing, during replacement of the insert.

Type 12.017.400 is intended to be used for applications, in which valves, ball valves or others are already installed for use as shut off devices during replacement of insert.

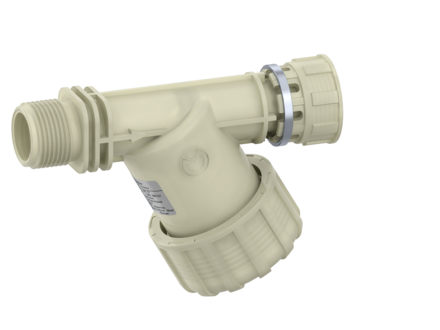

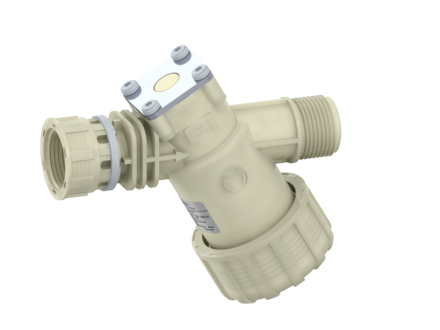

Type 12.017.500 integrates a shut off flow capability. The strainer is forcibly closed and an upstream shut off device is not required.