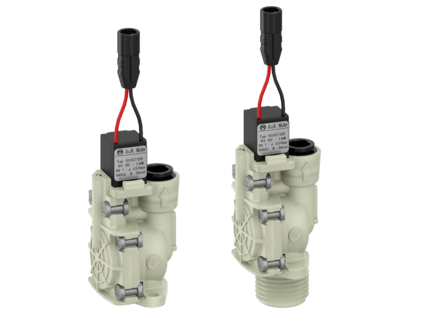

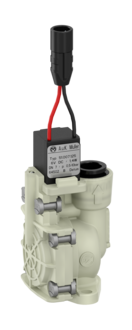

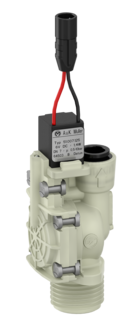

Bi stable axial valve, DN 7

2/2 way solenoid bi stable valve , DN 7, to control potable water with pilot controlled function, especially suitable for the application in battery operated electronically controlled faucets.

The power consumption is minimised by the use of impulse control (pwm), to achieve with primary cells a high capability with assured valve function.

The construction is in the external contour decreased to allow a smooth integration of the component into a small space. The user does not need to design a valve seat.