DIN 1717 compliant pressure relief function for pilot operated solenoid valves

Do it the right way – the pressure relief function in the outlet

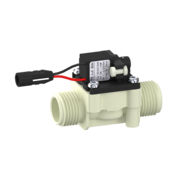

In the event of particularly high pressure loads, the pilot-operated solenoid valves of the 50 and 51 series from nominal width DN 7 can be optionally equipped with pressure relief on the discharge side to protect the drinking water network and components. The highlight: a diaphragm with pressure relief from 16 bar. Thanks to the intelligent pressure relief, the pipe system remains within the optimum parameters for operation and components are protected from damage.

In any application where a backflow preventer is installed upstream of a valve, significant overpressure can build up because the enclosed water volume cannot expand. The consequence: The valve can no longer switch or system components such as the backflow preventer, mixer tap or valve can be damaged.

Previous solutions for pressure relief work on the inlet side via the backflow preventer. This is a disadvantage because contamination of the drinking water network cannot be ruled out.

DIN 1717-compliant pressure relief on the outlet side protects against contamination of the drinking water installation

A. u. K. Müller now offers for the first time the solution of a valve with integrated DIN 1717-compliant pressure relief function. The overpressure can be relieved on the outlet side and the drinking water network remains protected against recontamination.

The essentials in brief

- New optional pressure relief function for high pressure loads for our pilot operated solenoid valves of series 50 and 51 (both monostable and bistable)

- Only DIN 1717-compliant solution: pressure relief takes place on the outlet side, thus eliminating the risk of reverse contamination of drinking water

- Equipped with pressure relief function > 16 bar towards the outlet (other pressures on request)

- DN 7 (DN 9, DN 13 optional)

- for controlling drinking water and physically and chemically similar media

- double filtering of the pilot water

- miniaturised design

- optimised pressure surge characteristics with low noise emission according to EN 60730 and EN 15091

Pilot operated solenoid valves DN 7 with optional pressure relief function

Application examples for pilot operated valves with pressure relief function

In electronic fittings, the shut-off valve is usually located behind the mixing chamber. To prevent cross-flow between hot and cold water, non-return valves are therefore installed on the inlet side. The medium enclosed between the inlet and the conventional valve cannot expand when exposed to high external temperatures. The result: the pressure between the non-return valve and the valve increases. The valve may no longer open. In the worst case, this can result in damage to the valve.

The solution: The pilot-operated solenoid valve with pressure relief function allows the medium to expand and permits relief on the outlet side with only a few drops.

Pressure surges from the piping system will reach a conventional inlet valve of the appliance, but will not recede due to the prescribed system separation with backflow preventer. The consequence: The water hammer from the drinking water installation will be coffered between the backflow preventer and the inlet valve.

The solution: The pilot-controlled solenoid valve with pressure relief function can relieve the pressure surge on the outlet side and the system components remain protected.

This is how pressure relief works

The pilot-operated 2/2-way solenoid valve with pressure relief function is designed for a pressure range of 0.5 to 10 bar. To protect the respective fitting from excessive pressure loads beyond the working pressure, a small spring-based ball in the diaphragm opens at a pressure of over 16 bar. Only small droplets of water escape in the direction of the outlet. This prevents a critical rise in pressure. The requirements for backflow prevention according to DIN EN 13959 are thus fully met.

The pressure relief diaphragm is currently implemented for all valves of series 50 and 51 and the nominal width DN 7. Optionally, the nominal widths DN 9, DN 10 and DN 13 are possible, as well as other pressures specified by the customer for pressure relief.

![[Translate to English:] Funktionsprinzip Druckentlastungsmembran](/fileadmin/akmueller/images/news/2023-07_Druckentlastungsmembran/Funktionsprinzip_Druckentlastung.jpg)

Do you have questions about relieving pressure on the right way?

Do you also have the problem of overpressure and are looking for an intelligent, DIN 1717-compliant pressure relief function? Then we have the solution for you. Call us right away or send us an email. We look forward to advising you without obligation.

A. u. K. Müller GmbH & Co. KG

Dresdener Straße 162

D - 40595 Düsseldorf

Telefon: +49 211 73 91-0

Telefax: +49 211 73 91-281

E-Mail: info(at)akmueller.de

A.K. Muller (UK) Ltd.

Unit 4, Brookside Business Park

Brookside Avenue, Rustington

GB - West Sussex BN16 3LP

Tel: +44 1903 788 888

Fax:+44 1903 785 817

E-Mail: valves(at)akmuller.co.uk

A.K. Müller France

10 Avenue du Gué Langlois

Z.A.E du Gué Langlois

F-77600 Bussy Saint Martin

Telefon: +33 1 64 62 95 14

Telefax: +33 1 64 62 95 12

E-Mail: info(at)akmuller.fr

A. u. K. Müller Shanghai

Rm26D, Huadu Mansion,

Zhangyang Rd. 838,

Shanghai, 200122, China

Telefon: +86 21 58 20 40 80

Telefax: +86 21 58 20 42 12

E-Mail: info(at)akmueller.de